FCC Medio Ambiente (FCCMA) is a leading company in the waste management and treatment sector in Spain. As a member of the Salamanca Hub4Circularity within the framework of the United Circles (UC) project, FCCMA will focus on the innovative transformation of waste into valuable resources, promoting the circular economy in urban and industrial environments.

Specifically, FCCMA’s initiative aims to convert waste streams currently deposited in landfills into biofuel, thereby reducing the total volume of waste and enabling energy recovery from organic waste.

Therefore, FCC Medioambiente’s main objectives to achieve this goal focus on three main lines of action.

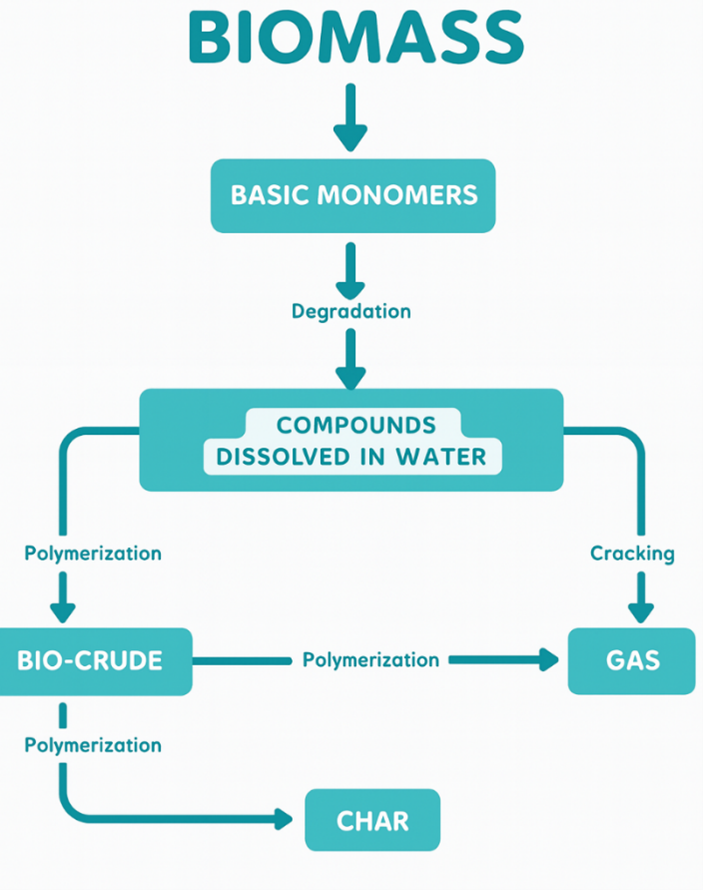

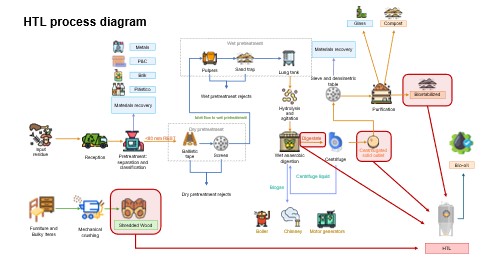

1. Hydrothermal Liquefaction Technology (HTL) Porcess

- Converts wet biomass into bio-crude through a thermochemical process in water at high pressure and temperature.

- Operates under subcritical or supercritical conditions (180–450 °C and 2–40 MPa).

- Does not require prior drying, which represents a significant economic and energy advantage over pyrolysis or gasification.

- By-products:

- Aqueous phase with soluble organics (usable for biochemicals or anaerobic digestion).

- Solid carbon-rich fraction (char).

- Light gases (CO₂, CH₄).

Input waste streams for the pilot reactor (currently sent to landfill):

- Digester outlet + biostabilized fraction.

- Digester outlet + structuring wood.

- Digestate fed to the centrifuge.

Reasons for selecting these streams:

- They have suitable characteristics for HTL (moisture, composition, structural material).

- They are non-valorized flows whose final destination is landfill.

Key parameters to optimize for maximizing yield and quality of bio-crude:

- Temperature (275–374 °C): increases conversion rate, but excessive values generate undesired products.

- Pressure (100–220 bar): keeps water in liquid state, essential for reaction kinetics.

- Residence time (20–60 min): balances conversion vs. char/gas formation.

- Solid/liquid ratio: influences viscosity, heat transfer, and pumping efficiency.

- Biomass nature: lipid-rich feedstocks improve bio-crude quality.

- Catalysts (acids, metals, zeolites): modify reaction pathways, enhancing yield and quality.

- Heating/cooling rates: affect energy consumption and intermediate degradation.

- Aqueous phase recycling: allows recovery of additional energy or chemicals.

2. Study of anaerobic digestion

The anaerobic digestion process enables the production of biogas through the decomposition of organic matter in the absence of oxygen. The aim of this study is to treat liquid flows with a high organic load, obtained during different processes at the plant, and to carry out fermentation to produce methane, which will then be used to generate energy.

The methane produced will serve as fuel for a cogeneration engine, transforming it into electricity to supply the plant. This configuration establishes a self-sustaining closed energy loop, where any surplus not consumed in the plant’s operations can even be sold to the grid.

In this case study, the raw materials selected for biogas production are liquid streams with high organic content, specifically:

- Surplus process water from the biomethanisation stage.

- Liquid flow obtained from the reject presses.

- Leachate generated during the aerobic digestion of organic matter recovered from the MSW pretreatment line and/or from the OFMSW process line at the facility.

Written by FCC Medio Ambiente